Practical deployments for advanced manufacturing and defense.

Market Realities

Advanced manufacturers face volatility, dependence, and waste that undermine resilience.

-

Raw Material

Price VolatilityFluctuating inputs pressure margins and planning.

-

Foreign

Supply ChainsExposure to policy shifts and export restrictions.

-

Recycling

Infrastructure GapsLimited domestic pathways for high‑value scrap recovery.

-

High Scrap

RatesValue is lost without on‑site recovery options.

Business Manufacturing

On-site recovery reduces risk and unlocks value directly from production scrap.

-

Mitigate Shortages

Recover critical inputs on‑demand from your own scrap.

-

Stabilize Costs

Reduce exposure to price spikes with internalized feedstock.

-

Unclog Bottlenecks

Shorten lead times and reduce logistics risk.

-

Manufacturing Assurance

Convert liabilities to assets at the source.

Defense Production

Critical minerals for the Defense Industrial Base (DIB) are secured at the source.

-

Secure Critical Inputs

Support tactical radios, aircraft batteries, NVGs, REPMs and more without leaving the perimeter.

-

Compliance Support

Examples include the Buy American Act, ITAR alignment, and Critical Materials Executive Orders.

-

Supply Continuity

On‑site recovery helps prevent production delays and losses.

Example Industries

Our solutions apply across diverse sectors where critical materials drive innovation.

-

Battery Industry

-

Printed Circuit Board (PCB) Manufacturing

-

Semiconductor Wafer Fabrication

-

Thin‑Film Solar Cell Manufacturing

-

Flexible Electronics Manufacturing

-

MLCC & Passive Component Fabrication

-

Roll‑to‑Roll Coated Packaging Materials

-

Advanced Composites Manufacturing

-

Metal Foil Rolling

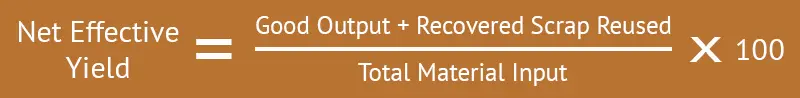

Increased Production Yield Comparison

Illustrative math for a large plant.

-

Baseline Yield

80%

From 10,000 tons of cathode input, 2,000 tons become scrap.

-

Yield with Cool Amps Deployment

96%

Scrap generated (20% of input) 2,000t

Recovered scrap (80% of scrap) – 1,600t

Remaining scrap after Cool Amps 400t

-

Net Effective Yield

+16 points

In this scenario, Cool Amps provides 1,600 tons of additional usable material from the same 10,000 tons of input.